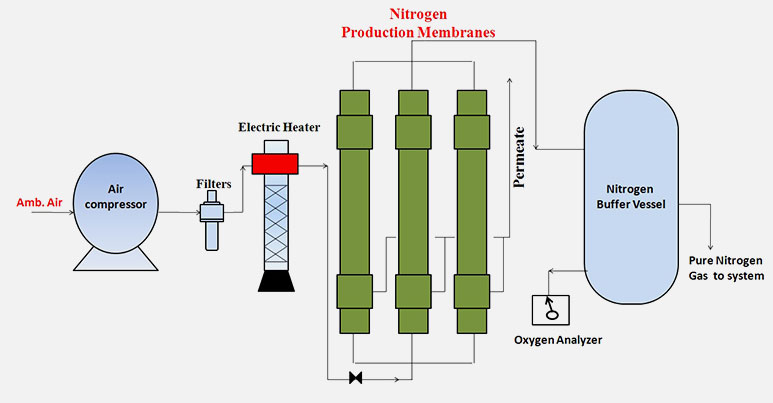

Membrane technology is regarded as an emerging gas separation technique in the industry due to the lower cost in both initial capital and energy consumption, if compared to cryogenic distillation and pressure swing adsorption. The typical design of the membrane gas separation technique is that the air is drawn from the ambient into the membrane module and the targeted gases are separated based on the difference in diffusivity and solubility. In the membrane module, oxygen will be separated from the ambient air and collected at the upstream due to the high diffusivity, whereas nitrogen will be collected at the downstream of the module.

A Nitrogen generator using membrane technology has the following characteristics:

| Capacity | 1 NM 3/hr to 5000 NM 3/hr |

| Purity | 95% to 99.9% |

| Pressure | 5 - 25 Bar g |

| Dew Point | (-) 70°C |

Nitrogen gas is used in many varying industries—a few of them are highlighted below: