VPSA ( Vacuum pressure Swing Adsorption ) Oxygen gas Generators are based on well proven technology using Zeolite Molecular Sieves (ZMS) & Vacuum system for regeneration . When ZMS is used in the VPSA process, nitrogen Molecules, having a higher diameter than oxygen Molecule, passes through the pores and are adsorbed. Therefore, the Oxygen is recovered, while Nitrogen is adsorbed. Adsorption of Nitrogen Molecules happens at Low pressure, which make it efficient & suitable for higher flow rates. In VPSA based Oxygen gas plants Regeneration process is dine with vacuum pumps, which ensures complete regeneration of ZMS. Adsorptive air separation is a cyclic process, in which adsorbent material is alternately, Fed with pressurised air to produce the required product and Regenerated by vacuum to remove the waste gases from the adsorbent.

Adsorptive air separation is a cyclic process, in which adsorbent material is alternately

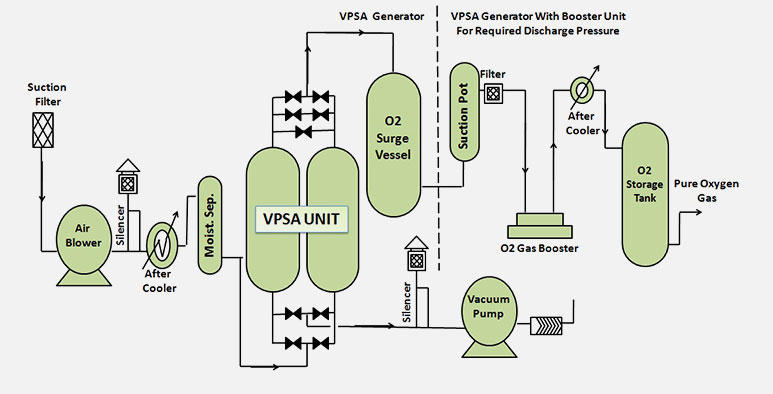

Purification:-The ambient (inlet) air is filtered before being compressed moderately by a blower system.

Adsorption:-The pre-treated air passes into a vessel containing zeolites to remove any moisture and CO2 and adsorbs the nitrogen while oxygen passes through the vessel outlet. Before the adsorption capability of the zeolite is exhausted the adsorption process is interrupted.

Desorption:-The saturated zeolite is regenerated (i.e. the adsorbed gases released) by means of pressure reduction below adsorption pressure. This is achieved by a dry running vacuum pump. The resulting off gas is vented to atmosphere. To maintain a continuous flow of oxygen supply a surge tank is installed and so the cycle continues.

Oxygen finds broad application in various technological processes and in almost all industry branches.

| Plant | VPSA Oxygen Generator |

| Product Flow (NM3/hr) | 50 to 5000 |

| Product Purity(%O2) | 90-95 |

| Product Pressure – Base Plant (brag) | -0.5 to 0.5 |

| Pressure with O2 Compressor (brag) | 2-150 |